Vertical RAM extruder

Vertical RAM Extruder

World-Class Solution in PTFE extrusion and UHMW-PE technology Most saled extruder for UHMW-PE extrusion and PTFE extrusion

Extrusion process with Keicher RAM extruders

Ram extrusion is a pressing process that allows the continuous production of profiles. Specially made of UHMW-PE (ultrahigh molecular weight polyethylene). The base material is UHMW-PE powder, which is fed into a cylindrical extrusion tube, compressed by means of a punch and simultaneously transported through the tube, which is heated to sintering temperature. The individual dosing charges sinter together to form a continuous extrudate.

Choose the highest productivity in the market

The PTFE RAM Extruder

or UHMW-PE RAM Extruder

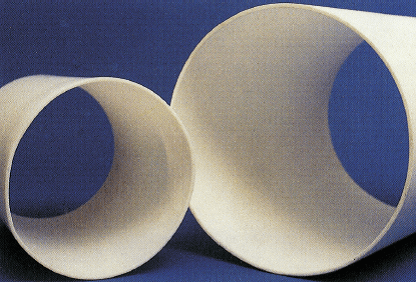

produces in the size 100 mm (4 inches), 300 mm (12 inches), 500 mm (20 inches)

and manufactured with a permissible trust load of 25 to 100 t.

Advantages of the Keicher RAM extruder or PTFE extruder

- Multiple tooling for tubes and rods is possible

- Touchscreen panel for programming of speeds and temperatures

- Short set-up times by simple and quick die change

- Consistent high quality of the products through permanent electrical measurement of extrusion pressure and precise temperature control

- Connection possibility for a heated / cooled mandrel, especially for the production of large, thick-walled tubes

- Low space requirement through vertical design

- Uniform and exact dosing through electronic controlled vibratory dosing balance

- Possibility of stepwise expansion to a fully automated manufacturing system through modular construction

- Lower compressive force and careful processing in tube extrusion through movable mandrel

- Automatic adjustin of extruder and heater to preexisting recipes

Available toolings

- Single rods

- Multiple rods

- Single tubes

- Multiple tubes

- Single profile

- Multiple profiles

Products with the Keicher RAM extruder

Extremely thin and thick-walled tubes, rods, profiles and hollow profiles for continuous production. Material that can be processed: PTFE, Teflon®, PEEK, UHMW-PW (ultra high molecular weight low density polyethylene), compounds, polyimide and polymide compounds as well as natural fiber material such as wood etc. with chemical additives as well as all ram extrudable plastics.

For additional information about our vertical RAM extruders, visit us on YouTube

Your direct contact

Should you require additional information about our products